Germany going strong

9 October 2006Windmölller & Hölscher - from plastics to print

When Converting Today arrived at the Lengerich headquarters of Windmölller & Hölscher, this major player was finalizing its preparations for an in-house expo to be held in October. The show would feature the company's latest developments in printing and extrusion, including two new dies capable of handling extreme layer ratios, a higher capacity, high speed turret winder, and - a “world first” in printing - a combined automatic impression setting and register set-up system.

Christof Herschbach, general manager marketing and business development, enthused: “We are in a happy position. Business is good, and this year we expect to reach a new record turnover of about €400M for all three business areas - print, extrusion and converting. We now have a range of over 50 different machine types - and many innovations. We are always making new developments to give our customers real advantages.”

The in-house event was held in the 5,000m2 technical centre on the Lengerich site, which has the production capacity of a small converting company. W&H regularly uses it for open house demonstrations during major shows such as K and drupa. “It has more capability that a stand at the show,” he explained. “Of course, we also use it for customer trials of film production and printing, for R&D work, and for training. We invest about eight per cent of our turnover in R&D, which has more than 300 dedicated employees. We hold over 1,500 patents as a result of this investment.

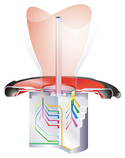

Among the latest developments demonstrated at the in-house event were the Maxicone and Maxicone C nine and three-layer dies. “These are designed to meet growing demand for barrier films in higher number of layers,” said Christof Herschbach. “It was a niche market, but now it's becoming more active. Maxicone gives greater flexibility, so the user can run barrier and film more economically than with other dies. It can also be used to achieve different advantages from the various film layers, to generate new and better film properties - so the film producer can develop new products and opportunities.”

There is also the possibility to use thinner films with less expensive resins, which was demonstrated at the open house, where a nine-layer structure was produced on both blown and cast film lines. Another innovation was the Easy Change module to ease switching a film line from one product to another - “at the push of a button”. Fully automatic, it is claimed to be 60 per cent faster than previous methods, saving material and costs.

‘World first’

Major savings in waste material are also claimed on the flexo printing front, for the Easy Set and Easy Reg systems - the “world first” starring attraction of the W&H in-house show. This combination of automatic impression setting and register set-up process, launched at the last drupa, has been improved and is now available as a standard option on all new lines from the company. Based on a camera system, it is claimed to be more accurate and much faster than existing methods. “It's part of a family of systems we are developing to help our customers become more efficient and, by saving time, give them more capacity for other jobs,” Christof Herschbach commented. “Ever decreasing run lengths mean high speeds are less important. Flexibility for change-over is the main consideration.”

Windmölller & Hölscher's wide range of flexo presses is illustrated by the three models in the demo centre - a Novaflex, an Astraflex and a Primaflex. There is also an improved version of the Filmex cast film line whose new features are a platform concept, screws for very smooth mixing, and chill rolls. Integrated with a new Filmatic TX winder, it also features an edge encapsulation system that uses cheaper resins to form film web edges that, when trimmed as scrap, can be recycled and cut waste costs.

Not to forget gravure, the facility is also home to a Heliostar press. “Gravure has seen a dramatic fall in cylinder prices,” confirms Christof Herschbach. “It is giving a real boost to gravure applications - bringing them nearer to flexo, and some customers still prefer gravure quality. It's seen as traditional but now has more innovations. We've had good results with gravure in recent years.”

Exports account for around 80 per cent of W&H sales: the company boasts over 5,000 customers in 131 countries. Apart from a new assembly plant in the Czech Republic, all production is concentrated in Lengerich.

“Our biggest markets are Western Europe and North America,” he emphasizes, “but Eastern Europe is growing dramatically. The domestic market is going down as customers move their manufacturing to Eastern Europe. We are also seeing huge investment in the plastics industry in the Near and Middle East, as well as the growing markets in Asia, especially India and China. China is very interesting; it has great potential.”

He concluded: “The converting and packaging business generally has not shown much growth but there is a high demand for used machinery. The extrusion side is growing. Many sack manufacturers are investing in new machinery, because the cement industry is booming. Overall, in the last 10 years we have delivered some 600 blown film lines, 600 flexo presses, 160 bottomers and 130 tubers."

Related ArticlesCase study: Primaflex pleases Schur

| Contact |

| Windmöller & Hölscher |