combibloc RS: Robust Structure provides even greater system stability and improved environmental performance

12 December 2016

combibloc RS: Robust Structure provides even greater system stability and improved environmental performance

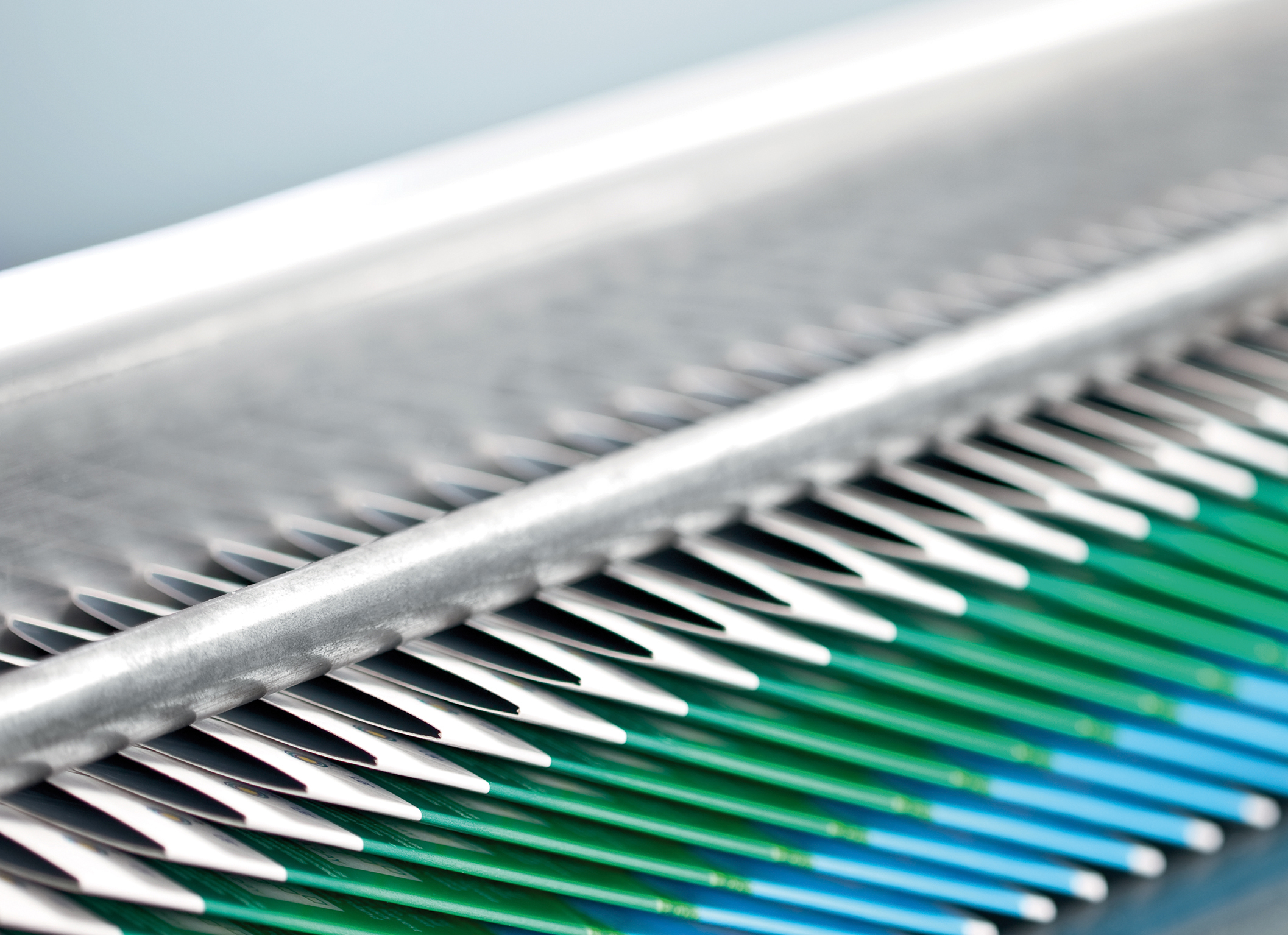

combibloc RS is a new composite structure for carton packs developed by SIG Combibloc that further improves system stability during processing, while contributing to even better environmental performance. In the medium term, this new laminate will become the standard composite structure for all combibloc and combifit formats used to fill liquid dairy products (LD) and non-carbonated soft drinks (NCSD) on SIG Combibloc filling machines.

Norbert Garitz, Head of Product Management Technology at SIG Combibloc: “For customers, the use of the new combibloc RS structure will mean a further improvement in our system robustness. The fact that less material is required also reduces the overall weight of the package, which in turn has a positive effect on environmental performance. The carbon footprint of each package will be reduced by up to six percent with the use of combibloc RS – compared to the previous structure. And of course, the proven quality and product safety will still be ensured”.

Another benefit with the ‘robust structure’ that gives the new structure its name: “It enables greater tolerances in machine settings during processing, particularly when sealing the top and bottom of the packages. The most important advantages of the new structure are fewer downtimes and even lower waste rates”, adds Dr Jannis Ochsmann, Technical Project Leader Global Technology at SIG Combibloc.

The combibloc RS structure is characterised by a new material composition that optimises the properties of the carton. A different polymer is used for the inner layers of the laminate compared to the standard structure that has been used to date. This makes the new standard structure particularly robust for processing. The outer layer, which is printed, and the innermost layer, which comes into direct contact with the product, were already optimised during the process of developing the current standard structure. These are characterised by particularly good printing properties and outstanding sealing and opening performance. “For SIG Combibloc, combibloc RS represents the next key stage of development in ensuring that customers receive exactly the products that the market needs, while being economical for our customers,” says Norbert Garitz.